A good beer takes time to mature – and the same applies to malt. This is why BESTMALZ® has committed itself to slow malting. But what does that mean exactly?

The elaborate malting process consists of cleaning, steeping, germinating and kiln-drying. The germination time triggered by steeping has a decisive influence on the quality of the malt. As the brewers’ yeast cannot process the starch in the grain, preventing fermentation, the starch must be converted into fermentable sugars. This takes place later in the brewing process, but malting creates the basis for this by causing the grain to germinate. This activates and boosts the enzymes required by the grain to grow, the yeast to ferment and therefore the brewer to brew.

Why is slow malting better?

The process of germination in the malthouse tricks the grain into believing it is undergoing natural growth, so to speak. Whereas germination is triggered by moisture in the ground, in the malthouse this occurs in the steep and on germination beds. The more time the grain is given for this, the closer the process is to the natural course, which normally takes several weeks. The gentler the germination process, the more active and energetic the enzymes that are essential for brewing. If the germination period is interrupted by drying, the stronger grains are at a more advanced stage of germination than the weaker ones. Inversely, germination and enzyme production are more uniform the longer the process.

Uniformity a great advantage

This uniformity is again a great advantage in the brewing process as malt with a homogeneous quality is easier to handle and is more predictable. An important factor to ensure homogeneous germination, apart from the germination period, is the amount of grain processed at one time: If up to 240 tons of barley are steeped at the same time, as is usual in large germinating plants, homogeneous germination is not possible. The depth of the grain on the germination bed should also be as shallow as possible to ensure that the grain can germinate uniformly. At BESTMALZ® the maximum batch size is 60 tons with a maximum depth of 70 cm, enabling it to absorb water more evenly.

Many facets to slow malting

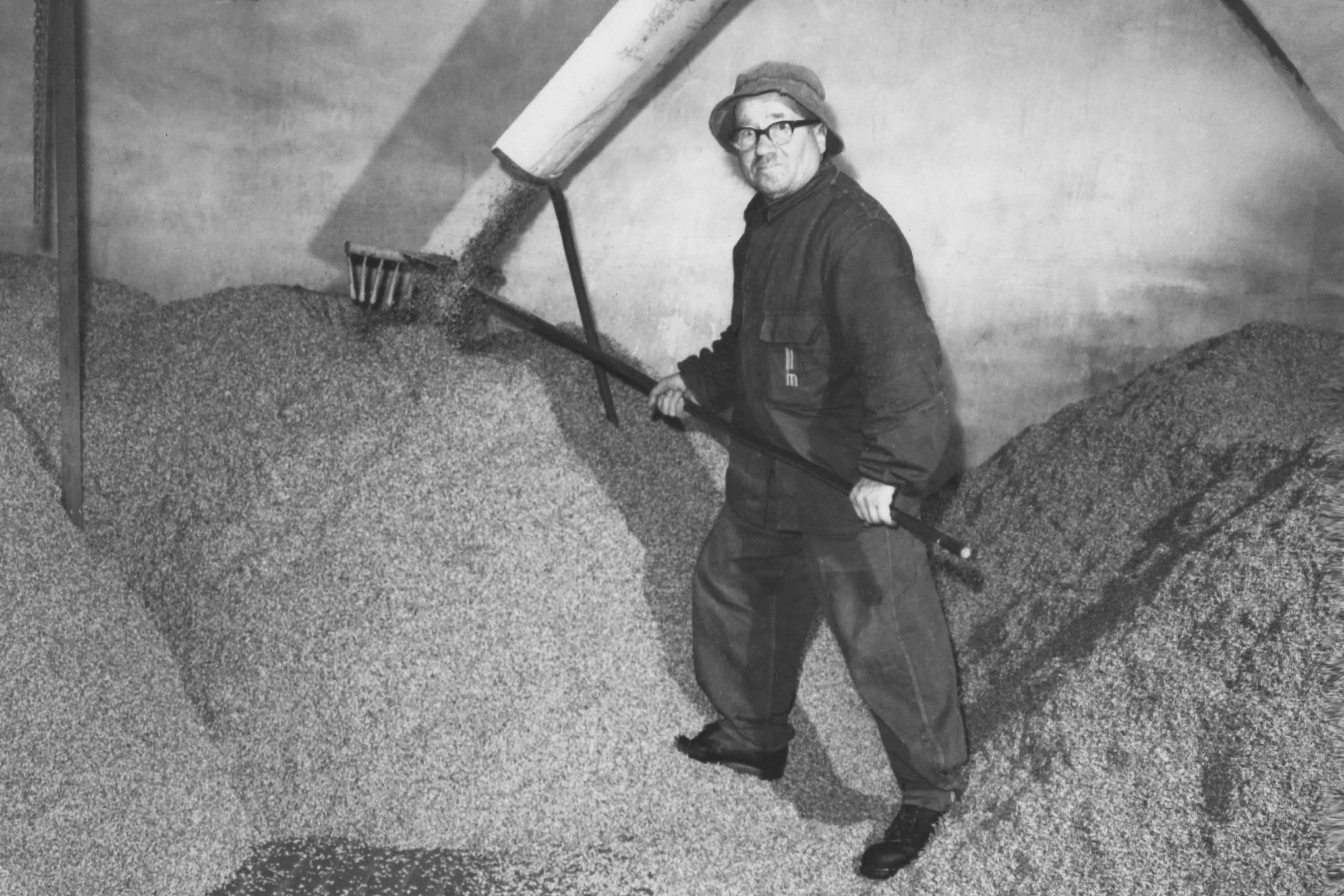

To sum up, slow malting means transforming grain to malt more gently and slowly. To start with, the grain is steeped twice, which takes between 20 and 44 hours at BESTMALZ®. Then, the grain is germinated over six days in flat germination beds with a large surface area. Having a large surface area and keeping the depth of the malt to a minimum are an advantage during kilning, too, as it means that temperatures can be kept low, which again has a positive impact on the flavor of the malt.

Generally speaking, slow malting is more complex, but is the only way to meet the high quality standards at BESTMALZ®.